What is Asphalt?

The word Asphalt originally derived from latinization of the Greek work Asphaltos and based on late latin words asphalton or asphaltum. In ancient civilizations asphalt is used for pasting cement joints and in the Middle East it was vastly used for road paving and waterproofing which are current major applications of asphalt.

Basically asphalt is combined set of aggregates from crushed rock, sand, gravel, slags or bitumen. Nowadays, use of by-products and wastes are also common – such as sludge or construction wastes – resulting in higher sustainability of asphalt. The result of this mixture is a black, sticky and high viscosity blend in solid or semi-liquid form which is relatively homogenous and suitable to expand over flat layers.

How is asphalt produced?

Asphalt is produced through mixing and blending several aggregates at an asphalt plant in high temperatures usually from 150-180 degrees Celsius. Asphalt plans could by mobile as well in order to produce the asphalt blend on site.

Producing Asphalt at different temperatures

In order to achieve different specifications for different applications, the asphalt can be made in different conditions which most effective one is the temperature. Below is a general categorization of asphalt making:

|

Asphalt Production Method |

Temperature of the Blend (°Celsius) |

Suitable Bitumen Used for the Blend |

| Hot Mix Asphalt | 120-190 | Penetration Bitumen |

| Warm Mix Asphalt | 100-140 | Soft Penetration Bitumen |

| Half Warm Asphalt | 70-100 | Soft Penetration Bitumen |

| Cold Asphalt | Without Heating | Emulsion or Foamed Bitumen |

Asphalt Applications

While major application for asphalt is road paving, considering the variety of specifications, it can be used in several sectors including the below:

- Transportation (roads, railway beds or airport runways…)

- Building construction (floorings, roofing…)

- Industrial (ports, landfill caps …)

- Recreation (playgrounds, running tracks, tennis courts…)

- Agriculture (greenhouse floors, barn floors…)

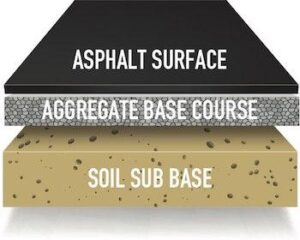

Layers of Asphalt Paving

Asphalt Paving consists of several layers, from ground to top consequently as below:

- Sub-Base and Sub-Grade: Preparation of the foundation with suitable clay or sand base aggregates

- Base Course: Most important layer to distribute the force traffic through the pavement layers

- Binder Course: Binder courses are implemented to stand the shear forces below the asphalt surface and reduce rutting sufficient stone-on-stone contact and stiff and modified binders such as Gilsonite.

- Surface Course: Surface course is the top layer of the pavement and stands high traffic and environmental stresses while providing an even profile for the user and enough texture to ensure minimum and safe skid and rutting resistance.

Asphalt Binder

Asphalt Binder is a bituminous layer that can be added either to the Surface layer or as an extra layer called binder course below the surface to make a stronger bind with the base course.

Surface Asphalt Binder is an asphalt emulsion designed for tack coat for patching, paving, and coating. Asphalt Binder increases adhesion of bituminous concrete and coatings.

Asphalt binder as binder course is an intermediate course between the base course and the surfacing material consisting of medium-sized aggregates bonded together by bituminous material such as Molten Gilsonite.