Gilsonite Sealer and Gilsonite Driveway Sealer

Gilsonite Sealer

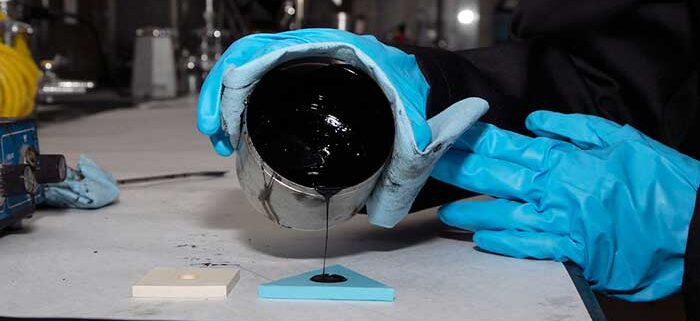

For Asphalt Pavements, a Seal Coating material called pavement sealer is applied. Sealer is a protective liquid coating. Pavement Sealer is applied to asphalt pavements surface to protect it against environmental corrosion effects. Gilsonite can used to make asphalt pavement sealers as raw material liquidized into a bituminous soft material in a suspension mix. Gilsonite Sealer can be applied easily on asphalt same as paint on wooden surfaces. Gilsonite Sealer has unique characteristics which provides strong binding with the asphalt bituminous content and provides the essential protection against cracking, especially from freeze/thaw cycle.

Gilsonite Sealer usage in streets and highways

Gilsonite properties provides longevity to asphalt based and emulsion based pavements. The nature of Gilsonite Sealer results in regeneration of molecular bonds within the pavement surface and assist in coloring effects providing a shinier fresh black surface. For this unique properties Gilsonite Sealer is applied vastly in Driveways and also in streets and avenues in addition to high traffic road such as highways. It is tested that applying Gilsonite Seal Coating maintenance every 1-2 years could result in increasing the pavement shelf life to 25 years. Also Gilsonite sealer could be blended with asphaltic pavement waste to make new pavement.

Benefits of Gilsonite Sealer

To summarize applying Gilsonite Sealer to asphalt pavements has the below advantages:

- Enhanced Visual Appearance

- Increase in Weather Resistance properties (anti-oxidation effect)

- Excellent Bonding with asphalt wearing course

- Crack Filling Effects

- Regeneration of Bonds on Wearing course

- Increase in pavement longevity

- Chemical Resistance (automotive leaks) and water resistance

- Stronger Frost Resistance in Cold Weather

- Easy to Apply

- Supply availability on commercial scale and vast availability on consumer scale

Gilsonite Sealer Prices

Since Gilsonite Sealer is liquid, unlike Gilsonite which is sold by weight, Sealer is sold by liters. On consumer level each liter of Gilsonite Sealer is purchased at 3.5-5 USD depending on the manufacturer and packaging. In USA, the largest market of Gilsonite Sealers in the world, the material is sold per Gallon around 15 USD and it is available in most of tool shops as driveways are an integral part of middle class Americans.

On Commercial level, Gilsonite Sealer Bulk price could be as low as 1.5 USD/Liter depending on the applied Gilsonite Supply and penetration bitumen prices in the manufacturing country.

Is Gilsonite Sealer Same as Liquid Gilsonite?

No, Gilsonite Sealer is a suspension blend of melted Gilsonite with another bituminous material while Liquid Gilsonite defines natural bitumen ores with very low softening point. Liquid Gilsonite could be used as pavement sealer, but the general application is in Oil Drilling. So Liquid Gilsonite is a natural resource while Gilsonite Sealer is a manufactured product.

Other Pavement Sealers

In addition to Gilsonite Sealer there are numerous sealers which are being applied internationally. Some are as below:

| Sealer | Pros | Cons |

| Gilsonite Sealer | As mentioned Above | Relatively Expensive |

| Asphalt Emulsion Sealers | Anti-Oxidant Less Air Pollution Better Smell | Staining Effects Needs Certain Temperature Unstable Pricing |

| Coal Tar Sealers | Weather Resistance Shiny Wearing Course Resistant to Petrol Based Chemicals | Possibility of Water Pollution, Health Damage and Environmental Damages |

| Fast Dry Sealers | Quick Drying Suitable for High Traffic Roads | Relatively Expensive Lack of Supply on Consumer Scale |

| Acrylic Sealers | Multi-Color Availability Weather Resistance High Traffic Spaces Application UV resistance Highly Durable Environment Friendly Low Maintenance Cost (reapplied every 7 years) | Very Expensive |

Zista Gilsonite Sealer Products

As a high scale Gilsonite supplier with investment in mining operations, Zista Gilsonite has access to variety of natural bitumen deposits in order to make a blend of Bitumen and Gilsonite. Production of Gilsonite sealer is a customized job at Zista Gilsonite and it is arranged by blending 50% of Solid Gilsonite powder into a low softening point Bitumen plus certain fuel additives. At the moment the supply is only available in Bulk and for commercial purposes and we hope to provide our packaged consumer friendly products within near future in order to expand our market size.

Advantage of Zista Gilsonite Sealer is customized formulation for buyers as per commercial buyers needs and requirements and the blending is executed in-house in Zista Group Oxidized Bitumen Facility.