All about Sulfonated Asphalt

Sulfonated Asphalt is a compound made from Sulfonating the Asphaltic material, synthetic and/or natural in order to make it solvable in water. The procedure contains special technology to be applied along with several chemical additives to change the nature of the asphalt for water solubility while preserving certain characteristics.

What is Sulfonated Asphalt?

Sulfonated asphalt is partly water soluble, party oil soluble and partly solvable in both water and oil providing a high emulsifying property which makes it suitable to emulsify with both fresh water and sea water along with the Oil, providing some unique characteristics to be applied in Drilling Fluids.

Sulfonated Asphalt is usually formed as a Blackish Brwon Powder and supplied in 50 pound sacks for application at the drilling sites. Considering the use of Synthetic bitumen as raw material, HSE regulations must be followed precisely for application of this drilling additive.

Benefit and features of using sulfonated asphalt:

- It is compatible with all water based drilling muds (WBM)

- Depressing the solid expansion of drilling chips

- Controlling HTHP Flow

- Helps maintain low shearing rate under HTHP

- Controls high temperature water loss

- Improves Filter Cake Quality and helps seal micro fractures

- Prevents slides and falls of wellbore walls

- improving lubricating properties of drilling mud

- Sulfonated Asphalt does not require use of emulsifiers for corresponding mixing

- Prevents Stuck Drill Pipe

- Its specific solubility in water and oil ensures excellent chemical and physical bonding properties

- Has Crack sealing effect

- Inhibits dispersion of drilled solids

Sulfonated Gilsonite

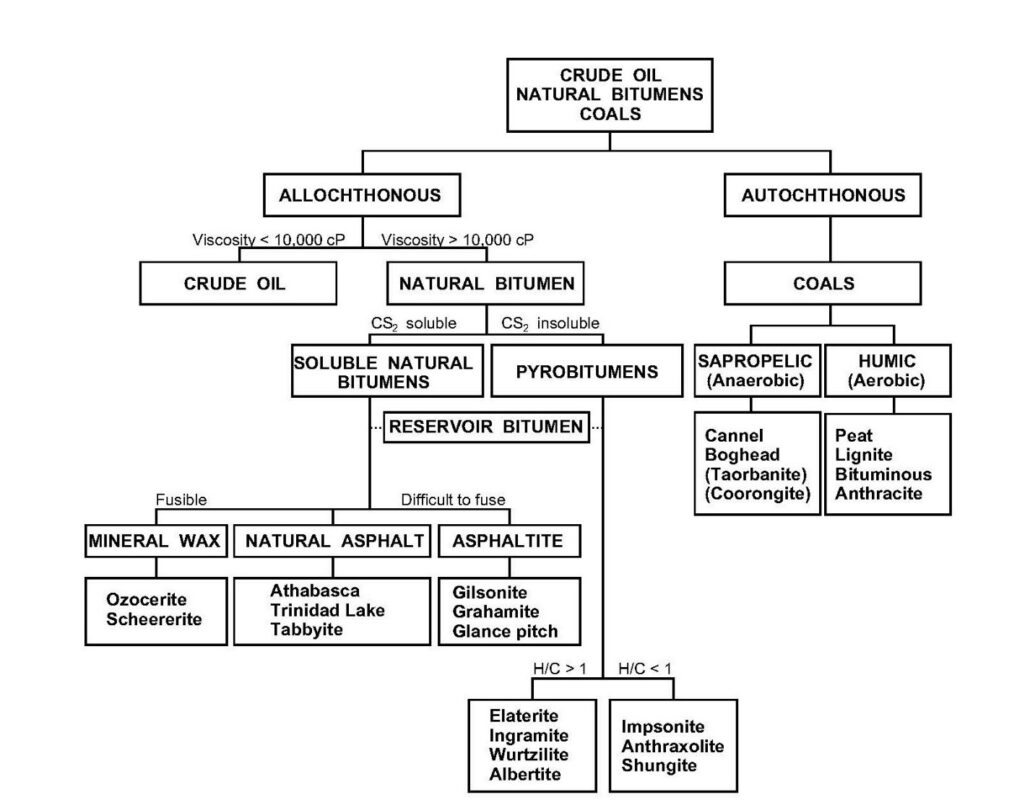

Basically Sulfonated Gilsonite is a sort of Sulfonated Asphalt, but with different properties and production method. Sulfonated Gilsonite is obtained from processing Natural Bitumen while Sulfonated Asphalt is made through sulfonating certain asphalt materials through a special method.

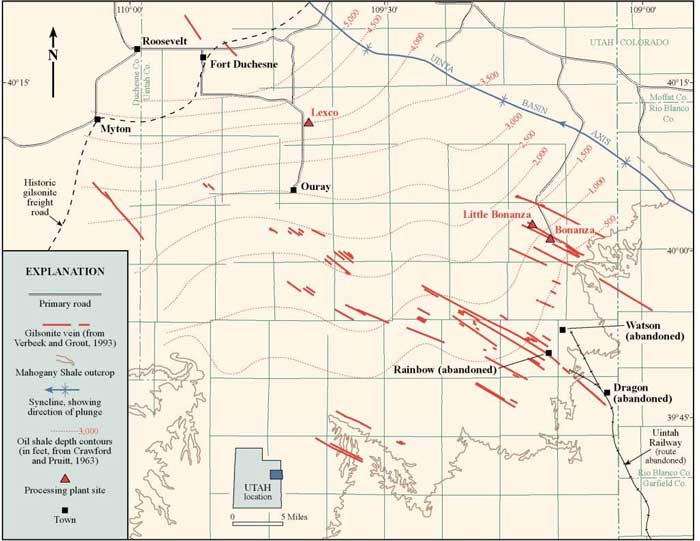

Most famous Sulfonated Asphalt in the world is SOLTEX additive formulated by Chevron Company and enhanced over 50 years of application. Following Soltex, American Gilsonite company has also provided a Sulfonated Gilsonite to the market with similar properties at 25-50% cheaper prices, while both products are highly expensive.

More economic prices for Sulfonated Asphalt can be obtained from Chinese factories actively using Iran Gilsonite for their formulation and improving the economics of their sulfonated asphalt products.

At Zista Gilsonite facility, we have proudly formulated our own Sulfonated Gilsonite in several grades to match same applications of Soltex Additive for high quality market and also an economical formulation of Sulfonated Gilsonite to match Chinese/Indian supply. Having first hand local access to the main natural resources, provides Zista Gilsonite with a competitive edge impossible to reach by Non-Iranian suppliers.

For more information about Zista Sulfonated Gilsonite, please visit the related product page: